Ford Sierra XR4x4

Curently undergoing a concours restoration. This XR 4X4 has been shipped up from Cornwall. The owners brought to us after it had spent a year in a local garage in which time it had only had the wings cut off and doors changed. They want to give it the full treatment, starting with stripping and blasting the shell. They have collected all new genuine Ford panels to rebuild the car to better than new.

1

With all the remaining trim and running gear removed the shell is now heading off to be blasted.

With the shell off at the blasters the running gear is now be dismantled ready for powder coating and detailing.

Fresh back from the blasters

Treated to a thorough coating inside and out of a zinc rust primer to prevent any surface corrosion whilst the fabrications are completed.

With the bare shell mounted on the roll over jig the fabrication will get under way.

The previous garage had started to remove the outer sill to gain access to the inner sill but unfortunatly that was where it was left.

With the remainder of the outer sill removed the inner sill and floor edge has been replaced .

With the inner repairs completed the new genuine ford sill was welded into place.

The new section of inner arch had to be fabricated and tacked into place.

The repaired inner arch will be filled, smoothed and eventually treated to a coating of diamond white.

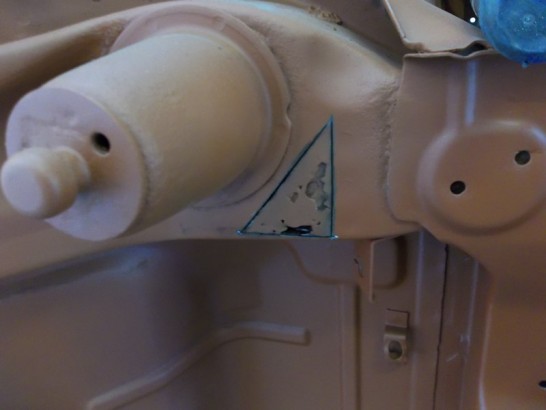

A portion of the rear chassis rails have also corroded through.

A small repair to one half of the rail was needed before a section of a repair panel could be grafted in.

With the drivers side of the floor completed its time to fix the passenger side staring with the inner and outer sills

A lenght of the floor edge and inner sill had to be replaced in preperation of the outer sill being fitted and as these are no longer available they had to be fabricated from scratch.

The genuine ford sill fits perfectly in place .

The corrosion has unfortunatly eaten its way into the suspension mounting pionts for the rear beam on both sides and will require some fabricated sections welded in.

The spring seat has also got a small ammound of damage

A couple of fabricated sections later and its as good as new.

With all the corrosion dealt with its time to prep the underside and engine bay for painting .

A good coating of primer over the underside and seal all the seams and its time to apply the diamond white topcoat.

With the underside and engine bay complete the shell can now be removed from the roll over frame on to stands and the roof, rear valance and wings can be fitted.

Watch this space for regular updates.

WANT TO KNOW MORE?

We do regular updates on our facebook page

Just click like to make sure you stay in touch!

Contact Details

Unit 13

Castleview Business Estate

Gas House Road

Rochester

Kent

ME1 1PB

T: 01634 818442

M: 07834 226246

E: andysautobody@btconnect.com

Monday – Friday 8am – 5.30pm